What We Do

We help organizations improve their operations by identifying and quantifying efficiency improvement opportunities (aka waste) in their processes. Gaining insight into the identity/quantity of waste involves comparing their Base or Useful Inputs to their Expended Inputs in order to determine the extent of the deviation (more on this below).

With the insight gained, plans can be put in place (with associated targets) to improve the processes.

Our approach to evaluating operations process efficiency is very different from the conventional approach.

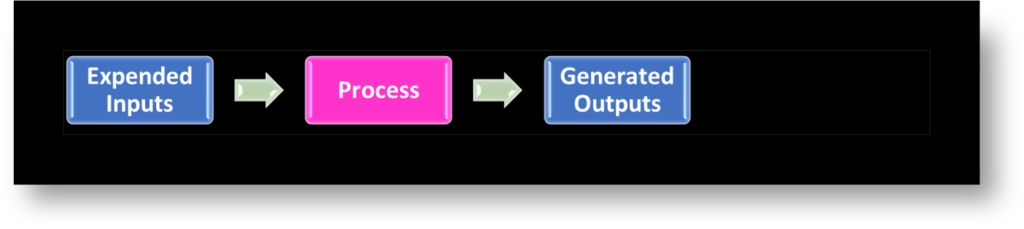

Our Conceptual Model

The Conventional Conceptual Model

Note: In both conceptual models, the blue boxes represent what either model believes are known values. The magenta and brown boxes represent unknown values.

Our approach is to directly evaluate efficiency. In our conceptual model, the Base Inputs reflect an/the ideal. If the Process is 100% efficient (zero waste), the Expended Inputs are exactly the same as the Base Inputs. If the Process is less than 100% efficient (i.e. there is waste present), then the Expended Inputs are greater than the Base Inputs. While this approach is extremely accurate, the challenge is that it is computationally more complex. However, at NPC Analytics, we have developed algorithms that overcome this challenge.

The conventional approach is to use productivity as a proxy for efficiency. In the conventional conceptual model, the Expended Inputs are (wrongly) assumed to be known a priori (i.e. before they interact with the process). While this approach avoids the computational complexities of our approach, it leads to inaccurate measures of waste/inefficiency. Here, productivity (the proxy for efficiency) is evaluated by dividing Generated Output(s) by Expended Input(s).

As mentioned above, the assumption that productivity is a good proxy for evaluating waste/efficiency is, more often than not, wrong.

To illustrate this lets look at the similarities and differences between productivity and efficiency.

First, let us show how the previously introduced Base Inputs and Expended Inputs are related.

The individual inputs (i.e. resources such as people, equipment/assets, goods & services) used/expended in any process will have one, two or all of the following 3 components: Value Adding, Value Enabling or Wasted. This gives us the following relation:

Expended Inputs = Value Adding Inputs + Value Enabling Inputs + Wasted Inputs

At NPC Analytics, we prefer to combine the Value Adding and Value Enabling components into a single category that we call the Base or Useful Inputs. This leads to the following relation:

Base (Useful) Inputs = Value Adding Inputs + Value Enabling Inputs

This ultimately results in the following relationship between Expended Inputs and Base (Useful) Inputs:

Expended Inputs = Base (Useful) Inputs + Wasted Inputs

While the Base (Useful) component contributes to generating the Outputs, the Wasted component does not.

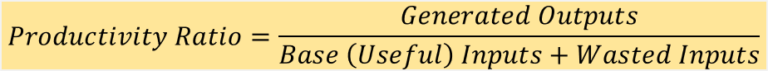

Productivity is a measure of the amount of output generated per unit of expended input. Productivity is mathematically expressed as shown below.

Rewriting the denominator to include both the Base (Useful) Inputs and Wasted Inputs gives:

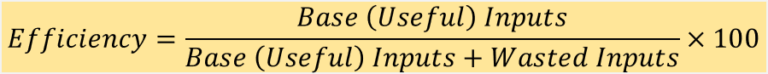

Efficiency is a measure of the percentage of the expended input that was useful (i.e. not wasted). Efficiency is mathematically expressed as shown below.

Rewriting the denominator to include both the Base (Useful) Inputs and Wasted Inputs gives:

The primary similarity between productivity and efficiency is that they have the same denominator (i.e. Expended Inputs).

Apart from the fact that their numerators are different, the other major difference between them is how they are affected by reductions in the denominator. While, at first, it might seem that both productivity and efficiency will increase if the denominator is reduced, this is not always the case. This is because the efficiency equation numerator (i.e. Base or Useful Input) is also present in its denominator.

Any reductions in the Base (Useful) Inputs leads to an INCREASE in productivity and a DECREASE in efficiency. This opposing effect is one of the reasons why, more often than not, using productivity as a proxy for efficiency leads to the wrong conclusion. Organizations that focus only on reducing the Base (Useful) Inputs will always become less efficient. The only way to ensure INCREASES in both productivity and efficiency is to reduce the Wasted Inputs component of the denominator.

Before efficiency can be calculated, organizations need to have the ability to identify and quantify the Wasted component of the inputs/resources that they expend in their processes. It is the general inability for them to do this that makes them resort to using productivity as a proxy for efficiency.

Our IMPACTT service helps organizations accurately & cost effectively identify and quantify the Wasted components. The only other method/tool that can do this is Lean 6 Sigma. However, Lean 6 Sigma is cost and time prohibitive for small and medium sized enterprises/entities (SMEs).